Remote predictive monitoring with AMS 6500 Machinery Health Monitor

In order to sustain production and meet consumer demand, a sawmill needed to reduce losses due to mechanical breakdowns.

Laurentide Controls' technicians and engineers working on this project installed the AMS 6500 Machinery Health Monitor to continuously monitor the health of the most critical equipment.

Providing 24/7 visibility on equipment health

The AMS 6500 Machinery Health Monitor is a versatile system that can be deployed in a variety of configurations to provide online equipment health monitoring. It provides 24/7 visibility into the health and condition of assets, enabling rapid detection and response to breakdowns and maintaining production.

Continuous machine condition monitoring allowed our client to prevent potential failures more quickly than conventional methods. This predictive strategy allowed more time to plan and execute necessary maintenance work.

$965,000 in savings in seven months

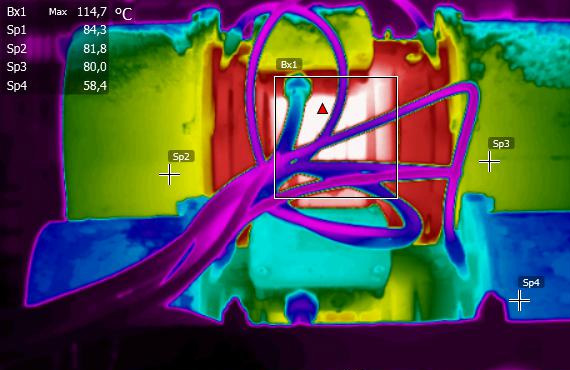

In just seven months, the implementation of the AMS 6500 Machinery Health Monitor system generated numerous alerts indicating potential breakdowns. By systematically analyzing vibration data, bearing problems were identified. By changing defective components during planned shutdowns, vibration levels returned to normal. In addition, asset condition monitoring provides the opportunity to improve existing maintenance strategies.

Our website uses cookies. By continuing to browse our site you are agreeing to our Cookie Policy.

Predictive Maintenance