Precision and versatility

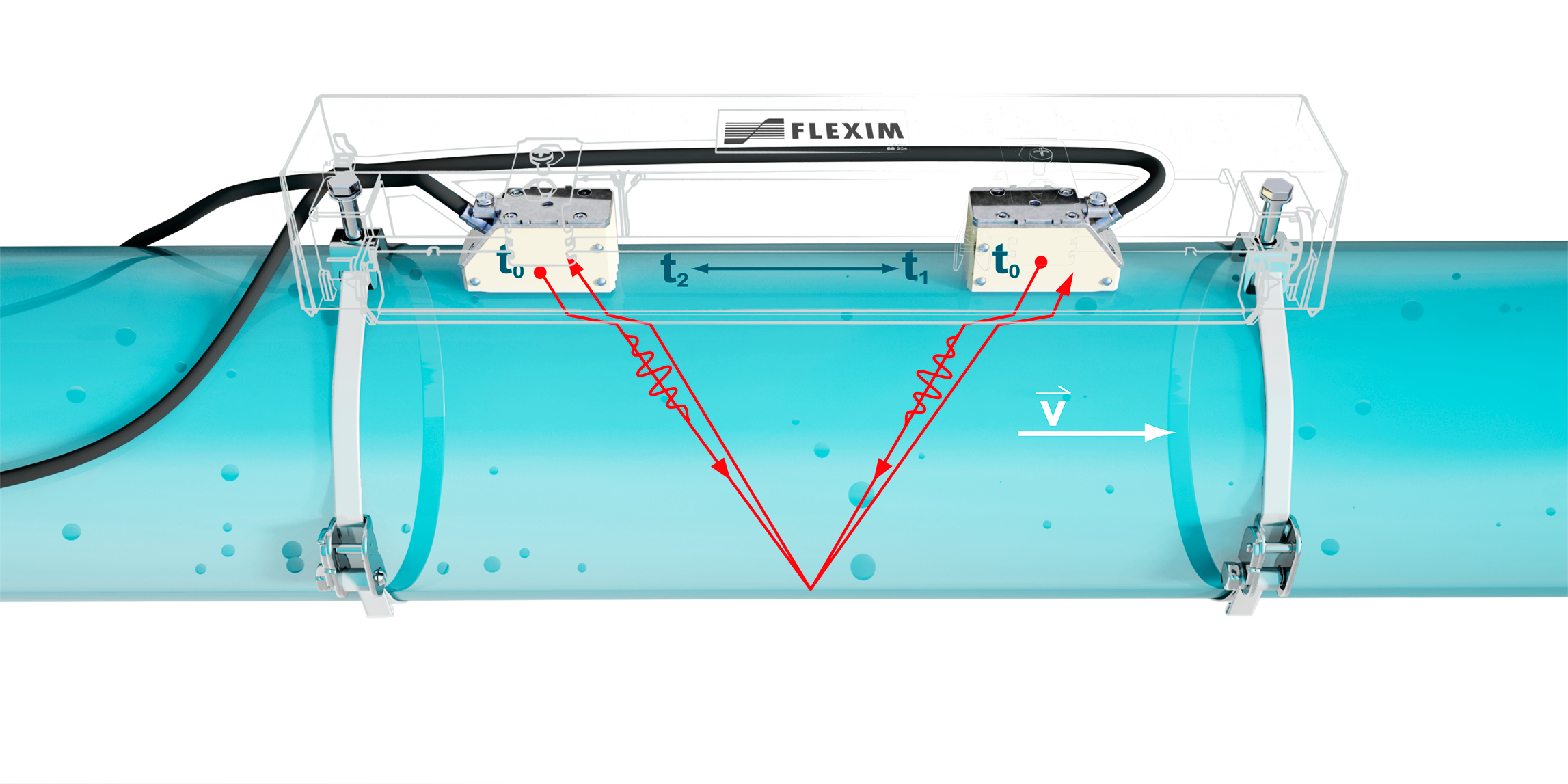

Clamp-on ultrasonic systems measure liquid-based thermal energy flows non-intrusively. By simultaneously recording temperature and flow at supply and return points, they provide accurate energy assessments. The FLUXUS® TE system integrates all the functions required for an energy meter: flow transmitter, temperature sensors and calculator. This calculator determines the actual heat output or total energy transported from the measured values, considering heat transfer-specific data such as enthalpy and heat coefficients.

Superior performance and durability

Non-intrusive ultrasonic measurement technology excels in monitoring, balancing and leakage control of compressed air networks. It is unaffected by moisture, oil or dirt particles, and operates without drift or maintenance. Its bi-directional capability enables precise balancing, even when flow direction changes. This technology also offers significant advantages for saturated steam flow measurement, enabling both low and high flow rates to be measured without reducing the pipe's cross-sectional area.

Diversified applications - Plant water inlet and outlet flow measurement (Environment/Energy)

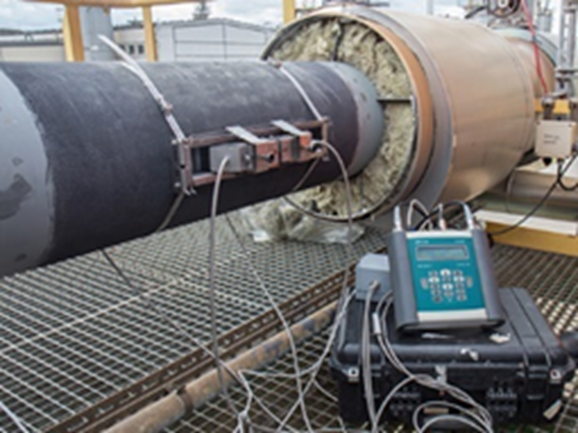

Non-intrusive ultrasonic flow measurement, using the transit time difference method, is versatile and covers liquids, gases and steam. Available in fixed and portable versions, this technology enables economical energy management. Fixed devices continuously monitor the main energy flows, while portable devices temporarily measure individual consumption. In the paper industry, measuring the flow of pumped raw water is a common application. FLUXUS® flowmeters can be used on concrete pipes up to 2 meters in diameter.

Measure corrosive liquors without intrusion with Flexim

Measuring the flow and density of black, white and green liquors presents challenges due to their corrosive nature, sediment and tendency to foul. Intrusive technologies have their limits, but Flexim's non-intrusive ultrasonic technology offers an advantageous solution, improving both maintenance and measurement performance.

Transparent integration and advanced verification with FLUXUS®

FLUXUS® transmitters feature interfaces for bi-directional digital communication, including Modbus, seamlessly integrating flow and energy measurements into energy management or process control systems. Flexim also offers advanced meter verification (AMV) for its measurement systems. This on-site validation does not interrupt measurements or operations and can be carried out by the user or Flexim service personnel.